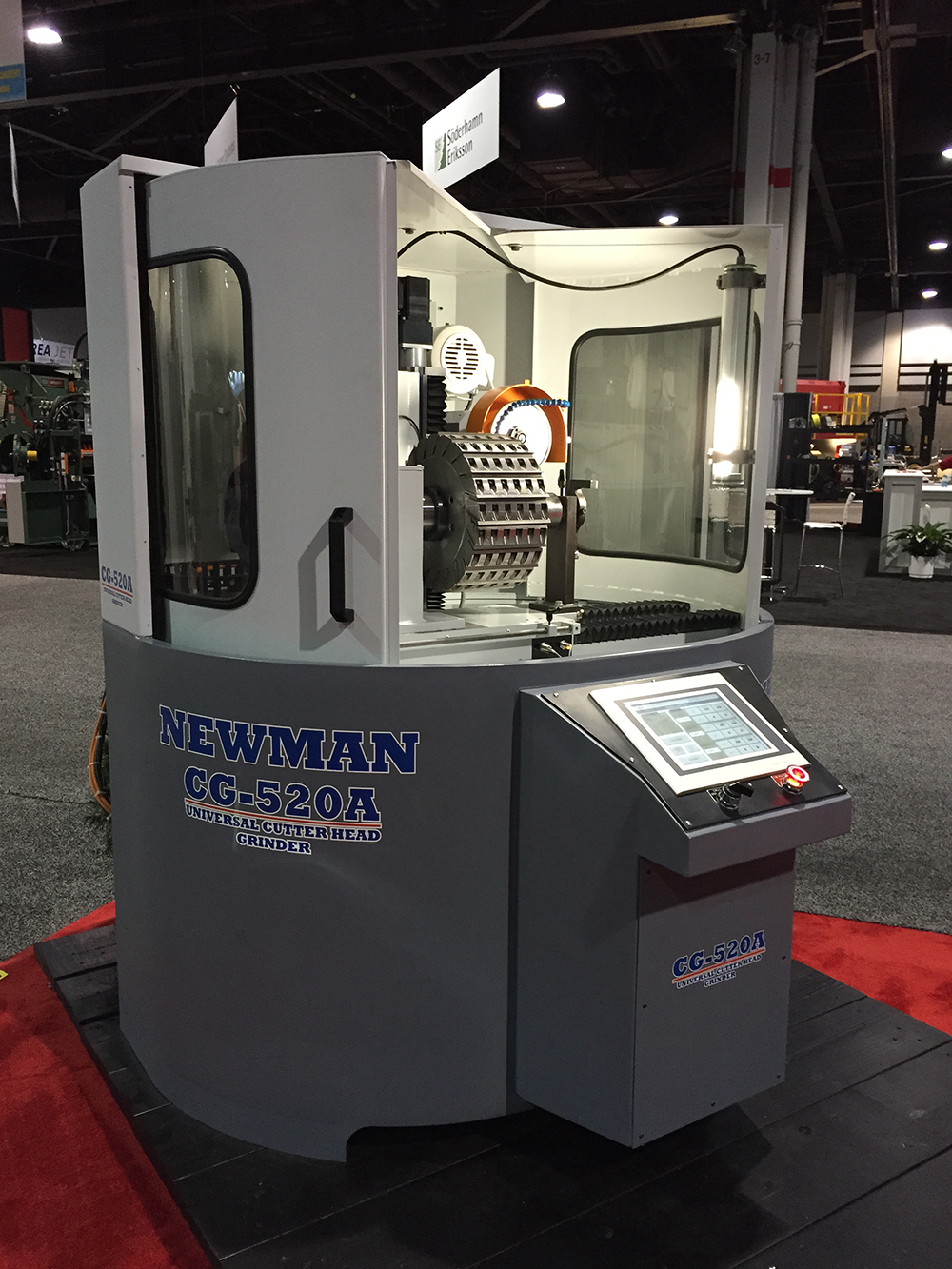

CG-520A Fully Automatic Universal Cutterhead Grinder

Video for CG-520a – Fully Automatic Universal Cutterhead Grinder

From the construction of the enclosure, heavy duty bearing rails for the sliding doors to the servo drive components, the CG-520A is built to provide quality grinding of all your cutterhead requirements in the most demanding environments.

Description

Video for CG-520a – Fully Automatic Universal Cutterhead Grinder

Advantages of the Newman CG-520A Fully Automatic Universal Cutterhead Grinder:

Extra Heavy Duty Construction

From the construction of the enclosure, heavy duty bearing rails for the sliding doors to the servo drive components, the CG-520A is built to provide quality grinding of all your cutterhead requirements in the most demanding environments.

Completely Enclosed Grinding Area

Completely enclosed grinding area provides for a safer and cleaner grinding room. The work area is completely enclosed by sliding doors and hood. The closed hood provides a tight seal with the coolant recovery tray. Coolant and grinding debris are carried away by the flooded coolant system and returned to the coolant reservoir. Since all the grinding debris and coolant are completely contained with the grinding hood there is no need for a pneumatic airborne particulate collection system.

Touch Screen Operator Panel

A high contrast LCD display operator interface provides a user-friendly system for programming the parameters specific to the head to the ground. The display keeps the operator informed of the current status by displaying cycles completed and total grind.

Fully Automatic Operation

The CG-520A Cutterhead Grinder is computer operated and fully automatic. The operator enters the setup parameters of the cutterhead; i.e. number of knives, number of cycles, amount of grind per cycle and direction. After each pass of the knife by the grinding wheel the cutterhead is indexed to the next knife and is held in place by high torque servo motor while being ground. After each cycle of the cutterhead the grinding wheel is moved the programmed amount for depth of grind and each knife is ground again. When the programmed number of grinding cycles is completed a spark out of two grinding cycles is performed and the CG-520A is automatically shut down.

Technical Information

| Head Indexing and Wheel Feed: | Programmable/Automatic |

| Minimum / Maximum Diameter: | 5″ Min. / 20″ Max. (127mm / 508mm) |

| Worktable Feed: | Air / Oil |

| Travel (maximum): | 15″ (381mm) |

| Adjustable Limits: | Proximity Switch |

| Speed: | Fully Adjustable |

| Index Method: | Programmable Number of Knives, Server Motor Infeed and Downfeed by Stepper Motor and Precision Gearbox |

| Grinding Spindle / Electrical: | 1-1/2 HP Wash Down Duty TEFC Motor, 3600 RPM, 230/460 VAC, 3 PH, Dual ABEC 7 Precision Bearings, with Sealed Lubrication, 8″ Diameter Grinding Wheel (9″ Diameter Max.) (consult factory for other voltages) |

| Coolant System: | 15 Gallon Tank with Casters, Sediment Tray, Full View Sight Glass, 5 GPM Pump (120 VAC), Wash Down Hose Included |

Specifications subject to change without notice.

You must be logged in to post a review.

Reviews

There are no reviews yet.